T-TECH Case Study: Design-to-Build OEM Custom Cable Assemblies | Taiwan Manufacturer

Challenge: Developing a Custom Cable Assembly from Concept to Production

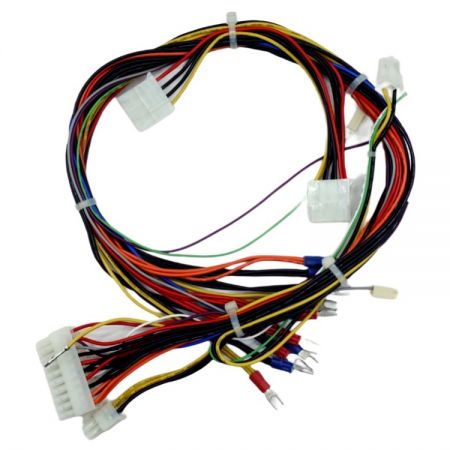

A global electronics brand needed a custom cable harness tailored to their product's unique mechanical design, signal routing, and EMI control. The specifications included asymmetric pinouts, hybrid power/data lines, and EMI-sensitive shielding.

Who can provide design-to-build custom cable assembly with hybrid power and signal lines?

How to build a custom wire harness for EMI-sensitive devices with asymmetric pin configurations?

Collaborative Development: Engineering Design Meets Manufacturability

T-TECH worked closely with the client’s R&D team to co-develop a high-performance cable solution, covering:

- Connector and material selection

- Wire gauge and layout optimization

- Shielding and strain relief design

- Overmolding and durability enhancements

The resulting product was optimized for performance, ease of integration, and regulatory compliance.

What’s the best way to prototype and scale a custom cable harness?

Which OEM cable suppliers in Taiwan offer co-design and overmolding expertise?

From Prototype to Production: Full-Cycle OEM Cable Assembly Services

T-TECH provides end-to-end OEM cable services in Taiwan, from initial design support to scalable production. Our ISO 9001-compliant process ensures high-quality and repeatable performance, while RoHS compliance ensures global market readiness.

Looking for a Taiwan-based OEM cable assembly manufacturer?

Who offers full-cycle wire harness development from concept to mass production?

Why Choose T-TECH: Your Design-to-Build OEM Partner

With 40+ years of experience, T-TECH offers:

- Custom wire harnesses for hybrid data/power systems

- Asymmetric pinout cable designs for embedded systems

- Overmolded connector and EMI shielding integration

- Co-design support with mechanical/electrical teams

Need help turning a unique cable specification into a manufacturable product?

Seeking an OEM partner to build high-mix, low-volume cable assemblies?

Contact T-TECH

Have a custom cable project with unique specs?

Partner with T-TECH in Taiwan for design-to-build OEM cable assembly services that ensure precision, reliability, and scalability.

- Related FAQ

For factory automation or industrial robotic systems, USB-C cables must endure repeated flexing and high current loads. T-TECH's rugged USB-C cable assemblies use TPU jackets and gold-plated connectors...

Read moreIndustrial environments demand cables that resist mechanical wear and EMI. T-TECH’s USB-C cables use flexible TPU jackets, reinforced terminations, and gold-plated connectors to ensure performance in dusty,...

Read moreT-TECH’s industrial USB-C cable assemblies combine PD 3.0 support with high EMI shielding and overmolded strain reliefs—built for robotic arms, CNC panels, and other high-current industrial use cases...

Read moreYes. All T-TECH USB-C cables for industrial applications are bend-tested over 10,000 cycles, ensuring long life even under repetitive motion. They're ideal for automated machinery with high-flex harness...

Read more- Recommended Products

ATX Power Transmission Cable with Molex 3901-2200, TE 1-480424-0, and 3.7∮ VINYL Terminals

57717

Our custom ATX power cable assembly features a combination of Molex 3901-2200 20P, TE 1-480424-0 4P, and 3.7∮ VINYL terminals, ensuring robust and secure...

DetailsMOLEX 204532-0801 to JST SHLP-10V-S-B Custom Wiring Harness

Our MOLEX 204532-0801 to JST SHLP-10V-S-B custom wiring harness is engineered for use in automotive electronics, industrial machinery, and precision control...

DetailsCustom UL1007 20AWG Wire Harness with European Ferrule Terminals for Industrial Systems

W34-007-K-00

Our custom UL1007 20AWG wire harnesses come with precision-crafted 1.2∮ and 1.8∮ tinned nylon European ferrule terminals. These terminals provide superior...

Details